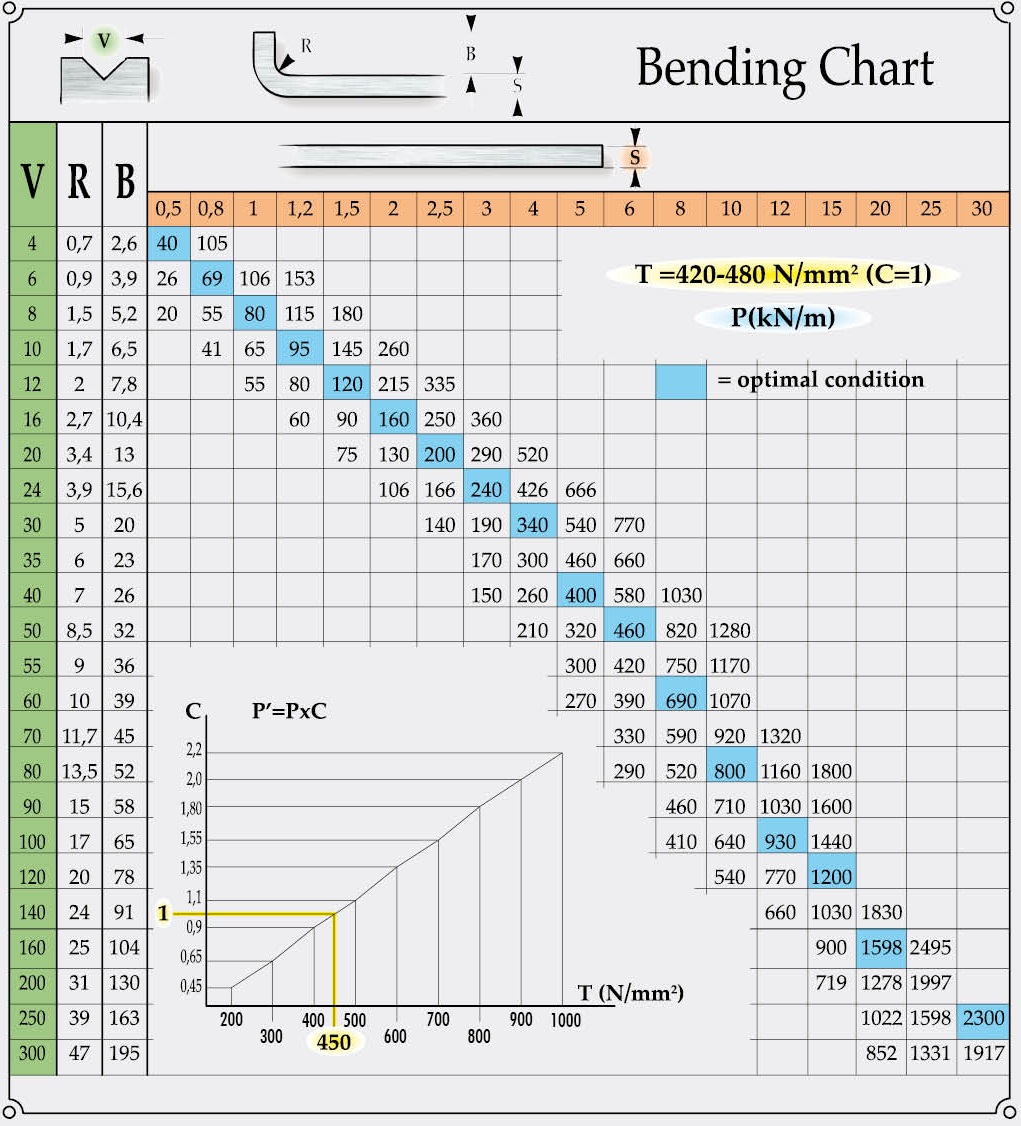

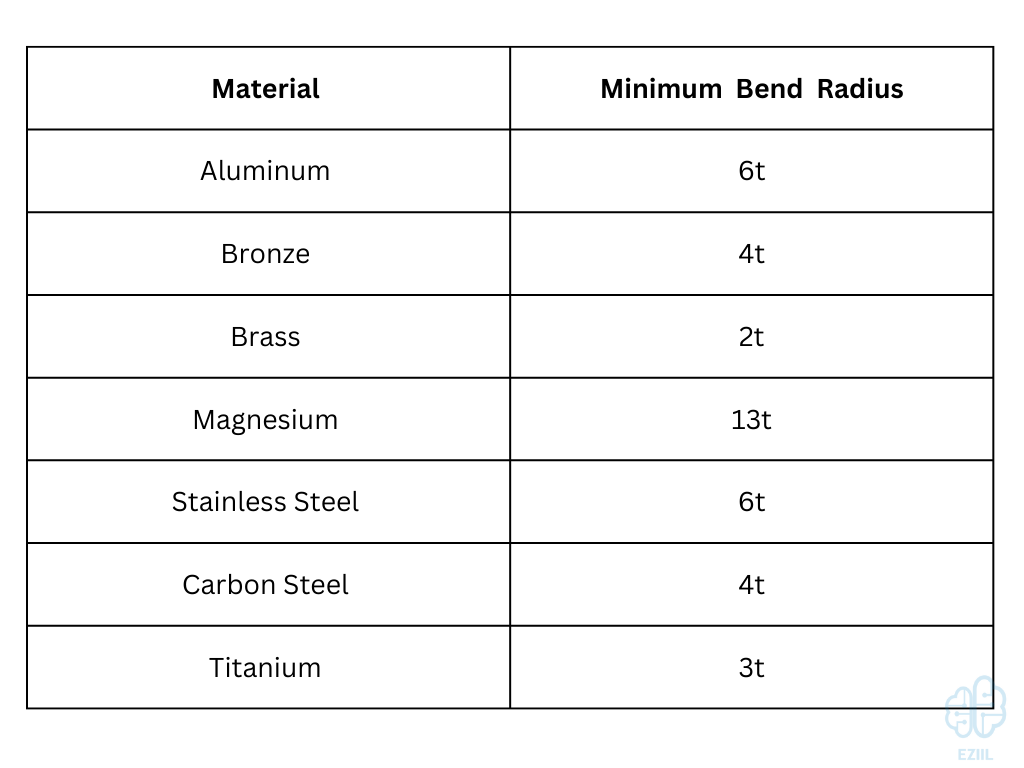

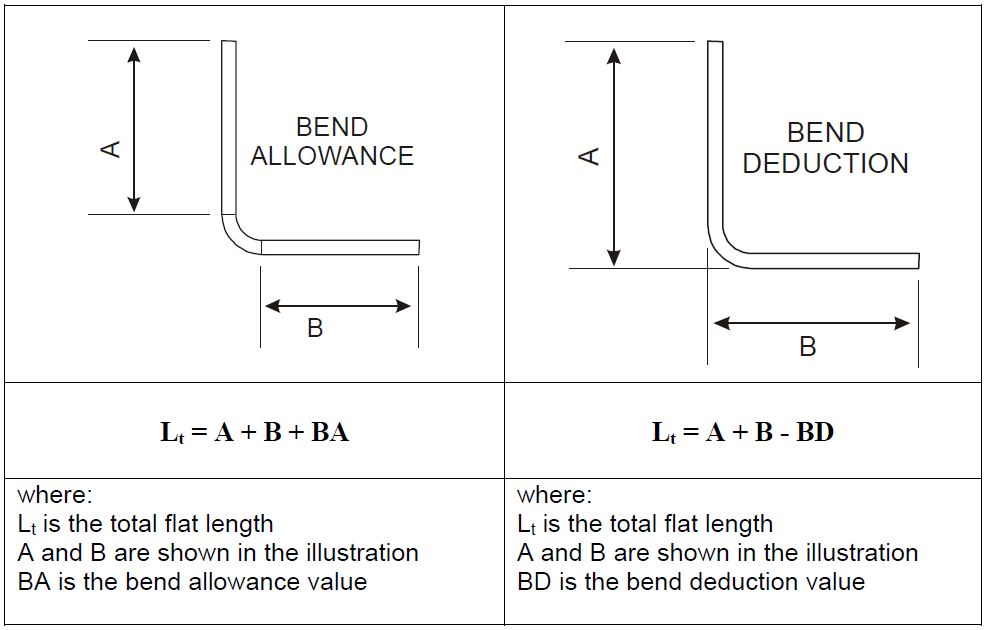

Minimum Bend Radius For Sheet Metal - A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The grain can be seen by. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

The grain can be seen by. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used.

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. The grain can be seen by. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

Sheet Metal Inside Bend Radius Calculator at Joel Watts blog

Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The grain can be seen by. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. A common rule of thumb for determining the minimum bend radius is based on the thickness.

Common sheet metal design Basic rules or guidelines Minimum Bend

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. The grain can be seen by. Use this page to choose bend values for.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. The grain can be seen by. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Use this page to choose bend values for.

Sheet Metal Bend Radius Full Guide Chart

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or.

Sheet Metal Bending Radius Chart In Mm at Kevin Conger blog

The grain can be seen by. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or.

Sheet Metal Bend Radius Calculator at Horace Winfield blog

Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. The grain can be seen by. A common rule of thumb for determining the minimum bend radius is based on the thickness.

Sheet Metal Bend Radius Chart Metric Ponasa

Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. The grain can be seen by. Grain direction is often specified on stainless steel in order.

Sheet Metal Inside Bend Radius Calculator at Joel Watts blog

The grain can be seen by. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Use this page to choose bend values for.

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe

A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. Use this page to choose bend values for sheet metal that are both manufacturable.

The Grain Can Be Seen By.

Grain direction is often specified on stainless steel in order to achieve minimum bend radius or to control spring back. A common rule of thumb for determining the minimum bend radius is based on the thickness of the sheet metal and the type of material used. Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.