Roboforming Sheet Metal - In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

Machina Labs Unveils Deployable Roboforming System The

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Podcast Sheet Metal Forming Goes HighTech with Robotics & AI

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Machina Labs uses robots to manufacture titanium sheet metal parts

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

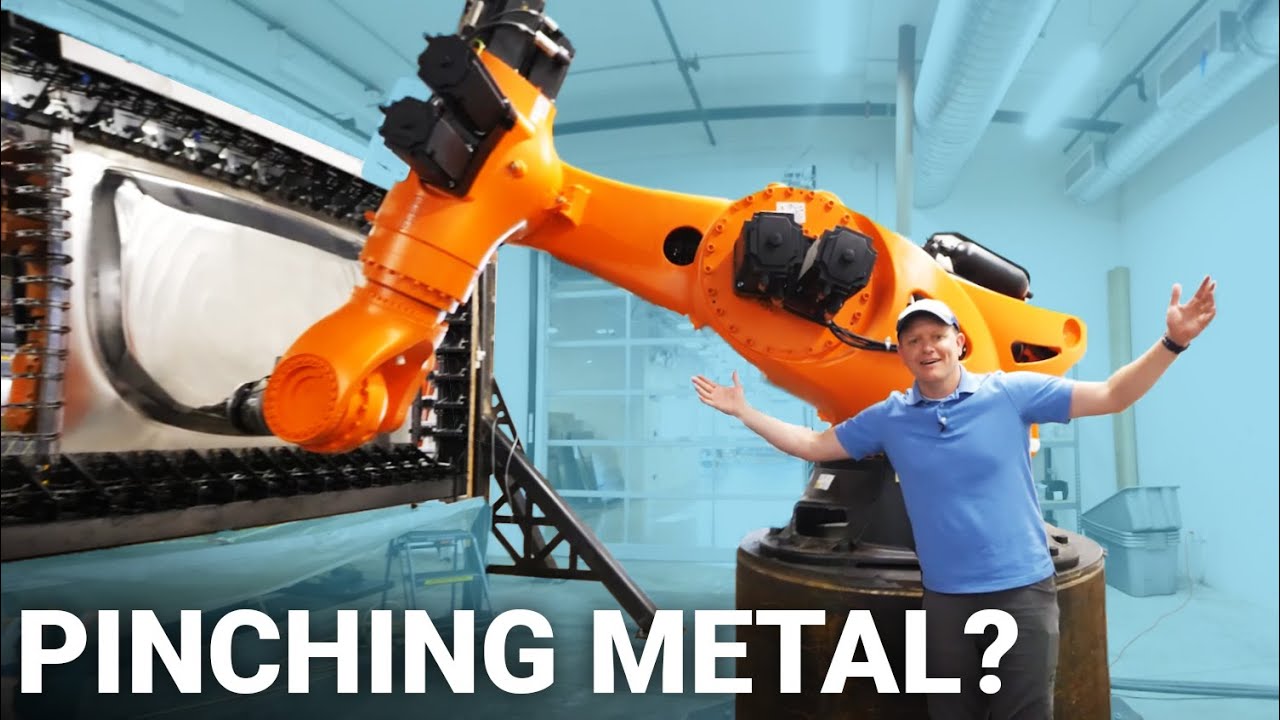

RoboForming (Incremental Sheet Forming), Educational Walkthrough, How

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Metal sheets forming with robots

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Incremental Sheet Forming for LowVolume Sheet Metal Fabrication

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

Roboforming a new way of shaping sheet metal Industry Insider The

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Setup for robotbased incremental sheet forming (Roboforming) at

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced. Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste.

Machina Labs Unveils Deployable Roboforming System The

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

Robot Arm Metal Sheet Incremental Forming YouTube

Roboforming™ large tooling surfaces allows composites manufacturers to significantly reduce lead times, cycle times, and material waste. In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.

Roboforming™ Large Tooling Surfaces Allows Composites Manufacturers To Significantly Reduce Lead Times, Cycle Times, And Material Waste.

In the field of sheet metal forming, the production of prototypes or parts in low batch sizes is being realized by high priced.