Plastic Sheet Forming - Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. 1m+ visitors in the past month Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. We are an authorized distributor.

Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. We are an authorized distributor. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. 1m+ visitors in the past month

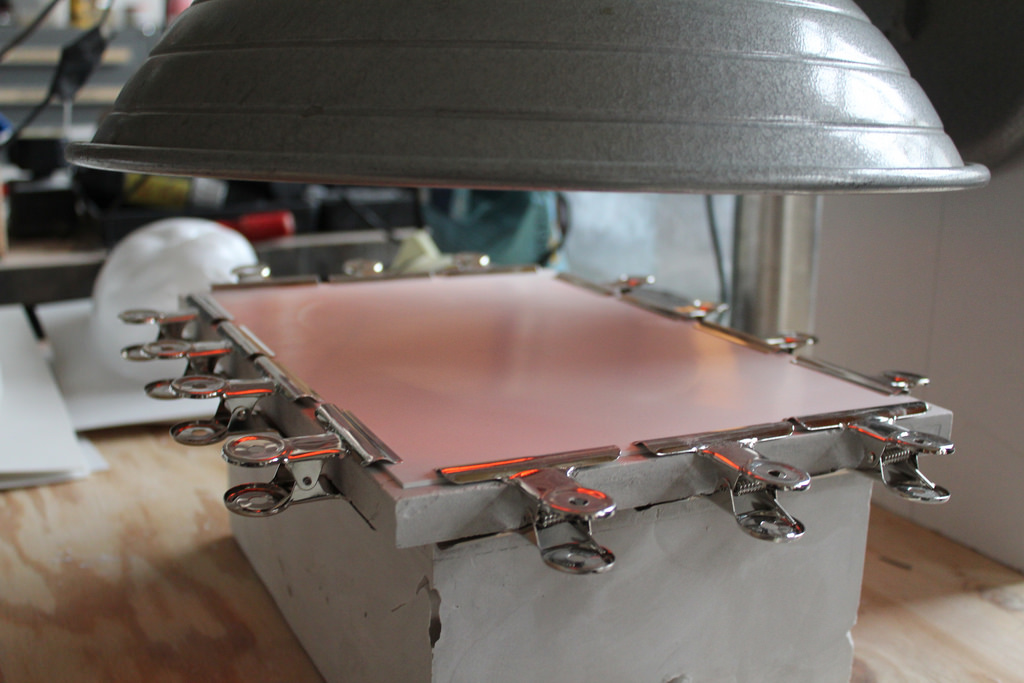

This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. 1m+ visitors in the past month We are an authorized distributor. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape.

Hips Thermoforming Sheet High Impact Polystyrene White Sheets

1m+ visitors in the past month This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. We are an authorized distributor. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Thermoforming is a process that uses heat and pressure to mold a.

PP Plastic Sheet Extrusion Machine For Vacuum Forming , 1 Year Warranty

1m+ visitors in the past month We are an authorized distributor. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. This article will teach you a super easy way to form acrylic.

Plastic Sheet Vacuum Forming at Simmons blog

Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. 1m+ visitors in the past month Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution.

Plastic Fabrication The Complete Guide In 2018 Wee Tect

We are an authorized distributor. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to.

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing

We are an authorized distributor. 1m+ visitors in the past month Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. This article will teach you a super easy way to form acrylic.

What is Thermoforming? Plastic Thermoforming Explained Productive

Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. 1m+ visitors in the past month This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution.

Thermoplastic industry Thermoforming of plastic sheets and foils

1m+ visitors in the past month This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material.

Plastic PP Stationary Thermoforming Packaging Sheet Extruder Sheet

We are an authorized distributor. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. 1m+ visitors in the past month Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. Thermoforming is a process that uses heat and pressure to mold a.

What is Thermoforming? Plastic Thermoforming Explained Productive

1m+ visitors in the past month Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution.

Plastic Sheet Vacuum Forming at Simmons blog

We are an authorized distributor. Thermoforming is a manufacturing process that empowers manufacturers with a versatile solution for processing plastic sheets. This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to.

Thermoforming Is A Manufacturing Process That Empowers Manufacturers With A Versatile Solution For Processing Plastic Sheets.

This article will teach you a super easy way to form acrylic plastic sheets without cracking, splintering, or destroying the sheet. Thermoforming is a process that uses heat and pressure to mold a flat sheet of thermoplastic material to a particular shape. 1m+ visitors in the past month We are an authorized distributor.